The Absorption Costing Method

Vaia is a globally recognized educational technology company, offering a holistic learning platform designed for students of all ages and educational levels. We offer an extensive library of learning materials, including interactive flashcards, comprehensive textbook solutions, and detailed explanations. The cutting-edge technology and tools we provide help students create their own learning materials. StudySmarter’s content is not only expert-verified but also regularly updated to ensure accuracy and relevance. For example, all machinery-related expenses, such as maintenance and depreciation, might be grouped into a single cost pool. This step ensures that costs are organised and efficiently allocated to products.

Period Cost Misrepresentation

This method allows the bakery to precisely monitor all expenses and establish prices for its cakes accordingly. Finally, Absorption Costing provides a comprehensive approach to cost accounting by including all manufacturing costs. This ensures no cost is left out, providing a more accurate and complete picture of a company’s financial performance.

Fundamental Analysis

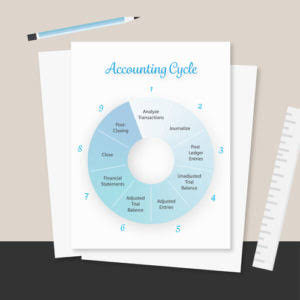

Absorption costing, also called full costing, is what you are used to under Generally Accepted Accounting Principles. Under absorption costing, companies treat all manufacturing costs, including both fixed and variable manufacturing costs, as product costs. Remember, total variable costs change proportionately with changes in total activity, while fixed costs do not change as activity levels change. These variable manufacturing costs are usually made up of direct materials, variable manufacturing overhead, and direct labor. The product costs (or cost of goods sold) would include direct materials, direct labor and overhead. Absorption costing includes fixed absorption costing manufacturing overhead costs as part of the product costs, while variable costing only assigns variable manufacturing costs.

- Absorption costing offers a comprehensive way to allocate costs, but implementing it efficiently can be complex.

- In contrast, variable costing treats fixed overhead costs as period costs and excludes them from product costs.

- By mastering absorption costing, CA students can become proficient in cost management and contribute significantly to organizational success.

- In the aerospace industry, it is applied to calculate the cost of manufacturing aircraft and spacecraft.

- Under absorption costing, the total manufacturing costs are spread over each widget, irrespective of the number produced.

Manufacturing Industry

This article will discuss not only the definition of absorption costing, but we will also discuss the formula, calculation, example, advantages, and disadvantages. Additionally, the software supports unlimited users, offers flexible customization options, and integrates seamlessly with third-party applications. Its adaptability and integration make it ideal for businesses looking to optimize full costing processes and ensure compliance with local financial regulations. In this article, we’ll explore the fundamentals of absorption costing, common challenges, and practical tips to optimize its application.

- This includes the costs of raw materials, labor, and both variable and fixed overhead expenses.

- It includes fixed overhead in the product cost, whereas marginal costing treats fixed overhead as a period cost and does not allocate it to products.

- This results in a total absorption cost of ₱7 per unit (₱5 direct costs + ₱2 fixed overhead).

- Once you complete the allocation of these costs, you will know where to put these costs in the Income Statements.

- This helps the company set competitive selling prices and identify the most profitable product lines.

Components of Absorption Costing

- This article will discuss not only the definition of absorption costing, but we will also discuss the formula, calculation, example, advantages, and disadvantages.

- This not only helps the management in evaluation of the financial condition of the business but also estimate the cost and plan production accordingly.

- In January, the company produced 10,000 widgets, each with a direct cost of ₱5 for labor and materials.

- The break-even analysis can decide the number of units required to be produced by the company to be able to book a profit.

- This characteristic of absorption costing can lead to differences in reported profits compared to variable costing, especially when there are changes in production levels and inventory levels.

- Period costs, such as administrative costs, are unrelated to production and must be reported separately.

Absorption costing is an accounting method that allocates all production costs, both direct and indirect, to individual products. This method ensures that each product carries its fair share of manufacturing expenses, providing a comprehensive view of production costs. Food and beverage manufacturers use it to determine the cost of producing various products, such as snacks, beverages, and packaged foods.

Difference between Absorption and Variable Costing

Absorption Costing collects data, including fixed overhead, to determine a product’s cost. This may lead to exaggerating the actual manufacturing Car Dealership Accounting cost and requiring more data for an exhaustive study. It lays out a simple and systematic costing tool for active businesses while considering fluctuating turnover, as costs are already fixed for the products. Direct labor costs are the wages and benefits paid to employees who are directly involved in the production of a product.

Finally, the costs are computed by allocating the cost pools to the products based on usage. This involves dividing the total cost of each pool by the total usage to get a price per resource unit, which is then multiplied by the amount used by each product. This step ensures that each product absorbs a fair share of the total manufacturing costs. Fixed manufacturing overhead costs remain constant regardless of the level of production. These include expenses like rent for the manufacturing facility, depreciation on machinery, and salaries of supervisors. To avoid this, businesses should implement a predetermined overhead allocation rate that reflects actual production volume.

- We have to either negotiate a higher contract price or look into possible cost optimizations.

- Fixed manufacturing overhead costs remain constant regardless of the level of production.

- In addition to the direct material and labour costs, this method also includes the necessary over head costs.

- By including fixed manufacturing overhead, variable manufacturing overhead, and direct materials cost, this method ensures accurate product pricing and proper financial reporting.

- These are individuals whose efforts can be directly attributed to a specific product’s manufacturing.

Absorption Costing Income Statement

This creates a misleading financial picture, affecting decisions related to pricing, production, and investment. Following these tips ensures accurate cost allocation, reliable financial reporting, and a more comprehensive view of your company’s manufacturing costs and profitability. Businesses adopt the absorption costing method to comply with generally accepted accounting principles (GAAP), making it essential for external reporting. Its comprehensive view of costs makes it a reliable choice for presenting financial statements and evaluating overall company profitability. Additionally, when there is unsold inventory, absorption costing can result in higher reported profits because fixed overhead costs are deferred into inventory until the products are sold. Absorption costing may report a higher net income during periods when inventory increases, as unsold units absorb a portion of the fixed manufacturing overhead.

Choosing between absorption costing and normal balance variable costing depends on how businesses want to allocate costs and report profits. Each method impacts how manufacturing costs are treated and reported on the income statement. This method ensures accurate product pricing and compliance with accounting standards like GAAP, making it vital for proper financial reporting and understanding a company’s true total cost of production. Additionally, it is not helpful for analysis designed to improve operational and financial efficiency or for comparing product lines. The main advantage of absorption costing is that it complies with generally accepted accounting principles (GAAP), which are required by the Internal Revenue Service (IRS).

0 comments

Write a comment